Quickly organize production to achieve delivery according to customer needs.

Consultation

PCB, active and passive components, all have rich and high-quality procurement resources.

Consultation

From material selection to shipment, it is strictly implemented in accordance with IPC610 standards and ISO9001-2015 standards.

Consultation

Have ERP system management to achieve product traceability.

Consultation Customized service

Customized service

Professional team for customized services

One-stop EMS service

One-stop EMS service

At the same time provide one-stop service for high-volume/small-volume customers

complete certification

complete certification

Flexible cost control

Flexible cost control

Lean production and increased efficiency to ensure optimal cost-effectiveness

Diversified Services

Diversified Services

Focus on industry, communications, new energy, digital electronics, medical products

High standards Refinement Zero defects

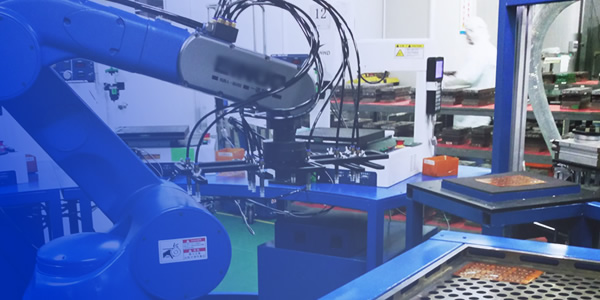

It is an EMS enterprise integrating PCBA product process research and development, new product trial production and mass production, sales, and services. There are two SMT production lines and 2 DIP production lines. They have advanced production and detection equipment, well -trained production teams, high -quality engineering teams and professional electronic components.

MoreSMT placement machine for placement of electronic components on circuit boardsSMT placement machines (also known as placement robots) place SMD electronic components onto PCBs pr···

Things You Must Know About PCB Screen PrintingPrinted circuit boards are an important part of electronic circuits. Over the years, their size has ···

Common SMT Process Defects to Avoid During SolderingAs more and more designs use smaller components with surface mount pads, surface mount technology (S···

Copyright © 2024 New Reach Electronic Technology (zhuhai) Co., LTD All Rights Reserved. | Powered by:ITM.CN